L3Harris Technologies is committed to the future growth of its local communities through investments in school STEM programs and competitive robotics teams.

“As technology develops at lightning speed, we recognize the need to develop highly-skilled individuals in a multitude of specialties to ensure industry can meet the demands of our customers worldwide,” said Renee Swan, L3Harris vice president of Human Resources. “That’s why we’re proud to partner with colleges and universities in our local communities, like Rochester Institute of Technology, to lean forward with programs that inspire and educate students in the latest innovations in engineering and manufacturing.”

L3Harris has a strong partnership with the Rochester Institute of Technology (RIT) in particular, hiring many engineering and technology students as summer interns or new college graduates, according to Balaji Suresh, L3Harris vice president of Operations. In fact, RIT is the most-common alma mater among the company’s Communication Systems employee population, with more than 500 alumni.

“We are fortunate to have a world-class institution in our backyard and are thrilled to support the integration of emerging technologies and operational excellence concepts in RIT’s curriculum to help prepare the next generation of manufacturing and industrial engineers,” said Suresh.

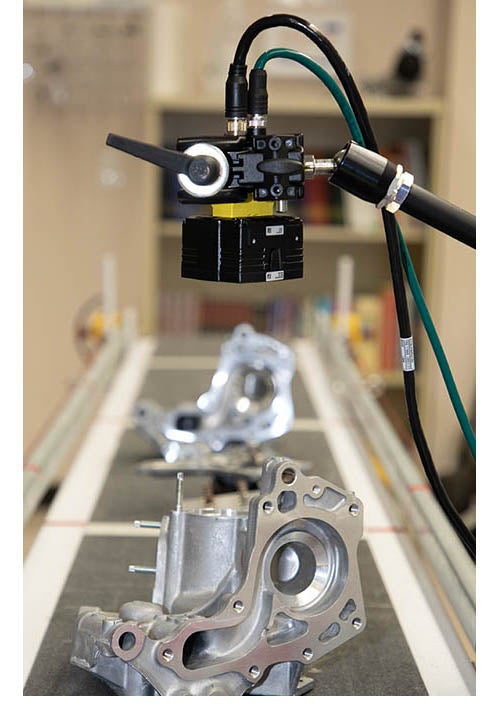

Recently, L3Harris helped source augmented reality, programmable torque driver and artificial intelligence inspection equipment, among others, for RIT’s Toyota Production Systems Laboratory.

L3Harris Operations representatives reached out to the lab to gain perspective on what it teaches students about Lean Six Sigma tools and advanced manufacturing technology, according to Ryan Esse, L3Harris director of Manufacturing Engineering.

After a discussion with Tony DiVasta, the Lab’s director and former L3Harris employee, the two teams realized there was an opportunity to collaborate and provide new Artificial Intelligence and Machine Learning (AI/ML) technology to the school, said Esse.