Product Specifications

L3Harris provides both highly survivable distributed control systems and redundant PLC-based control systems for naval, Coast Guard and auxiliary ships. Our systems incorporate propulsion, electrical, HVAC, auxiliary and damage control systems into a single integrated solution. Our systems provide operators with a common look and feel for all system operations and allow any system to be operated from any shipboard position subject to strict station-in-control transfer functions and configurable operator authorization profiles. The integration of the systems also eliminates standalone OEM control equipment, reducing space, weight and cabling, providing increased supportability through commonality.

Our human machine interface (HMI) technology provides operators with an intuitive Windows™ or Linux-based user interface. Our displays have undergone extensive design optimization to ensure that operators are provided with the information they require to perform their tasks without overload from extraneous data. Our operator-configurable alarm filtering features reduce the number of nuisance alarms without disabling vital alerts.

An embedded training system can be provided with our control systems to provide training to operators using any operating position that is not in use for machinery plant operation. The embedded trainer is based on a real-time, physics-based model of a ship's machinery plant, which provides highly realistic training that includes cascading effects of equipment causalities. The trainer can be used as a standalone trainer or a team trainer with or without an instructor. The instructor facility provides a toolset to define preset scenarios involving plant malfunctions and also allows a free-play mode where the instructor can modify plant status at any time.

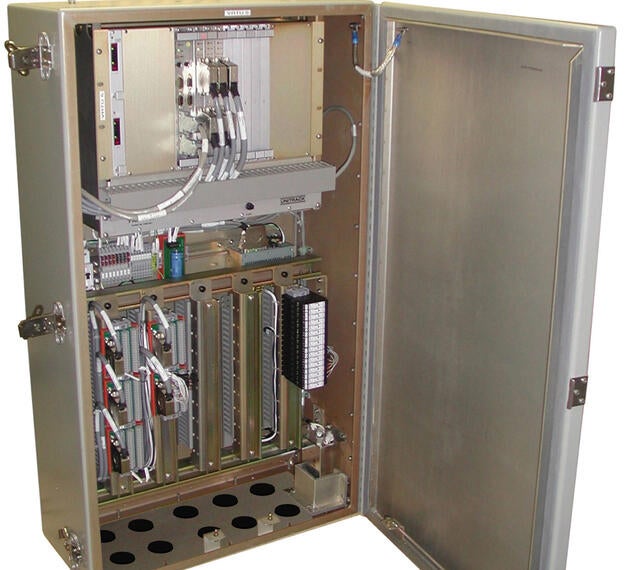

L3Harris has implemented several control system architectures and hardware solutions as required for specific program needs. We work closely with our customers to select the architecture and system components that best meet the program requirements at the lowest acquisition and installation cost. We have recent experience with the following architectures and hardware implementations:

- L3Harris peer-to-peer replicated database

- Fully redundant PLC

- Linux Real-time Operating System

- Windows™ Embedded

- PC Control with Remote Input/Output modules

- Rugged COTS Input/Output modules

Our system engineers are highly skilled at hull, mechanical and electrical (HM&E) operations. Their expertise in operational concepts and instrumentation design guides our control system development.

Our engineering process is based on an integrated systems engineering environment that captures requirements, concepts of operation and multiple system design artifacts to ensure complete traceability over the system design, implementation and test process. This process also auto-generates consistent sets of control system documentation to ensure that design documents match the control system implementation at all times.

L3Harris provides scalable skid or local control solutions for subsystems and equipment. We supply conventional hydraulic or electric steering system controls, water mist control systems and engine local control panels.