Overview

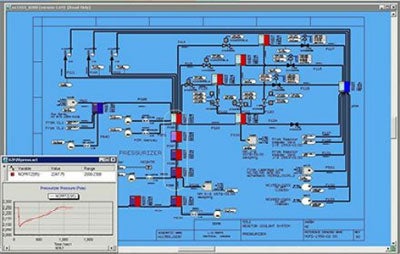

L3Harris’ advanced reactor and thermal-hydraulic models unlock maximum fidelity and performance from your simulator. The models are based on first principles and advanced numerical techniques, and are extensively proven with installations worldwide.

Advanced Reactor Kinetics Models

Comet™ and Comet Plus™ are advanced models for the simulation of reactor neutron kinetics based on a rigorous application of first principle physics and advanced numerical techniques.

Comet™ and Comet Plus™ are advanced models for the simulation of reactor neutron kinetics based on a rigorous application of first principle physics and advanced numerical techniques.

Advanced Steam Supply Model

L3Harris' advanced thermal-hydraulic model (ANTHEM™) is based on a rigorous application of the equations of mass, momentum, and energy conservation and implicit numerical techniques.

L3Harris' advanced thermal-hydraulic model (ANTHEM™) is based on a rigorous application of the equations of mass, momentum, and energy conservation and implicit numerical techniques.

Power Systems Resources

View the ResourcesRelated Solutions

Certifications | L3Harris Montreal, Canada

LEARN MOREAffiliations

Related News

Editorial | 02. 05. 2026

Al Seer Marine and L3Harris Deepen Strategic Agreement to Advance Maritime Unmanned Systems in the Middle East

Al Seer Marine and L3Harris have announced a strategic partnership combining UAE shipbuilding leadership with world-class autonomous maritime systems expertise. The collaboration will accelerate the development, integration, and deployment of advanced unmanned surface vessels across the UAE and broader region.

Contact Us

Related Domains & Industries

Solutions that solve our customers' toughest challenges.

view all capabilities