Enhanced Performance

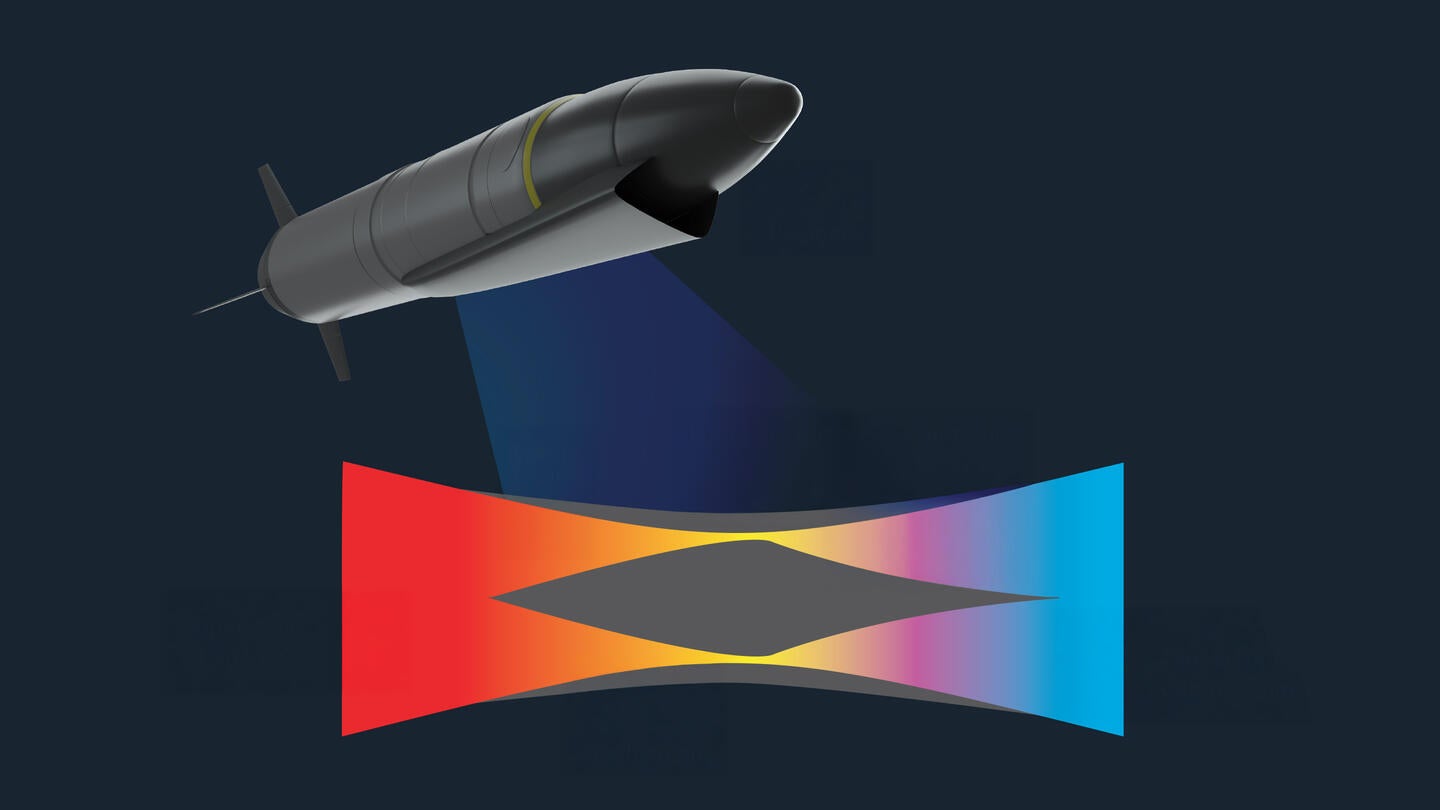

In missile applications, ramjet propulsion provides increased speed and range compared to similar munitions propelled by low-Mach turbine engines. This increased speed not only improves time-to-target but also enhances kinetic effects.

Reduced Cost

L3Harris is applying its industry-leading 3D printing technology to quickly and affordably produce ramjet propulsion systems at scale. 3D printing also unleashes new design possibilities that would not be possible to produce using traditional manufacturing methods.

L3Harris has increased its internal investments in developing ramjet technology by 170% over the past three years.

Liquid and Solid Fueled Options

L3Harris offers both liquid- and solid-fueled ramjet propulsion systems that can be scaled to meet a variety of mission requirements. Liquid-fueled systems typically offer higher specific impulse and can be throttled for varying thrust levels, whereas solid fuels provide consistent thrust once ignited. Liquid-fueled ramjets require more complex plumbing and fuel management systems, while solid-fueled ramjets are simpler in design, with fewer moving parts. In addition, solid-fueled systems are generally easier to handle and maintain and have a longer shelf life than liquid-fueled systems.

Decades of Experience

With more than 80 years of experience producing solid rocket motors for critical defense programs, L3Harris leverages its extensive expertise to build advanced ramjets. Our solid rocket motors feature state-of-the-art graphite composite cases, affordable advanced nozzles, and high-energy, long-life solid propellant. This rich legacy of innovation ensures that our ramjet systems are built on a foundation of proven technology and reliability.