Overview

L3Harris has always been known for delivering high-quality simulators. With the Orchid product suite, L3Harris continues this tradition with a complete, cutting-edge simulation software environment.

The Orchid tools have been highly integrated to create an effective and efficient working environment. Each tool follows a standardized approach, providing the same guidelines for menu structure, icons, documentation and even training material. By focusing on the use of common icons, layouts, themes and menus, we have been able to minimize our users’ learning curve in adopting the Orchid products.

Features and Benefits

Orchid features the latest in graphical user interfaces using an enhanced, modern look and feel, and providing an unparalleled level of customizability. Each Orchid application comes loaded with new features that help our users utilize our tools as efficiently as possible. User manuals, help menus and tool tips are all accessible directly from within the tools. All Orchid® tools also come with InstallShields, making each Orchid application easy to install and to upgrade to newer versions.

Our tools are now faster and easier to maintain than ever. Orchid supports recent releases of third-party software operating systems, database management tools and software compilers.

Using important feedback from our user community, we’ve incorporated hundreds of new features, making the Orchid product suite a powerful and complete set of tools for all your simulation needs.

With our complete Orchid product suite, we continue to provide the highest standards of quality to all of our customers, aiming for even higher levels of customer satisfaction.

Power Systems Resources

View the ResourcesThe Orchid® Suite

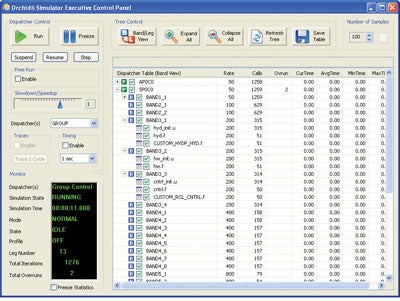

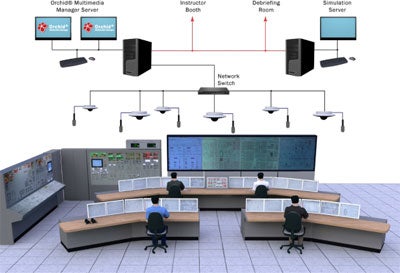

State-of-the-art Modular Instructor Facility for Controlling Simulator Training Environments

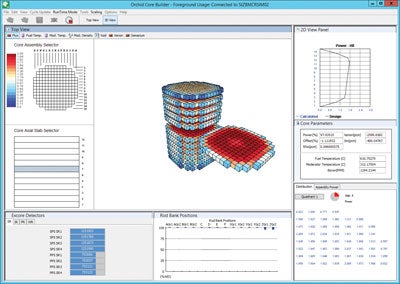

Design-Grade Neutronics Rapid Model Development

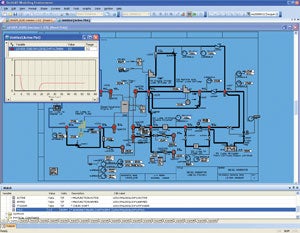

Advanced Real-time Graphical Component-based Simulation Environment

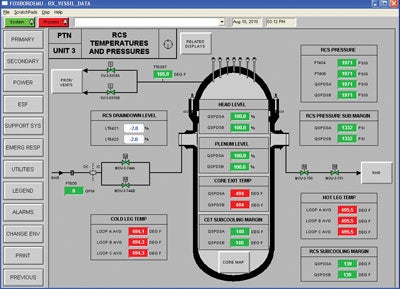

Simulator-Ready DCS Human-Machine Interface Simulation

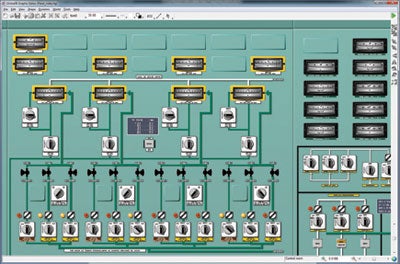

Development Environment for Graphical Control Panel and Purpose-built Schematics

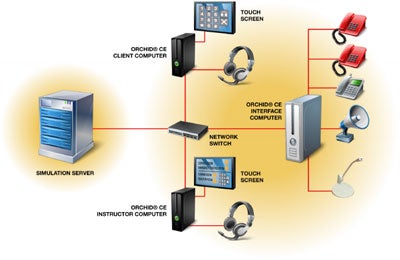

Extending the Benefits of Classroom Simulation while Offloading the Full Scope Simulator

Graphical Real-time Simulator Task Scheduler

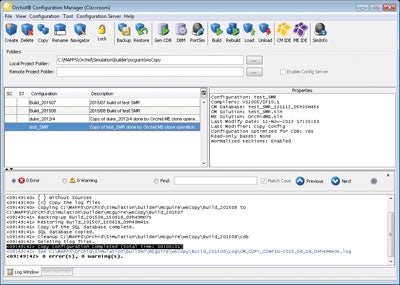

Fully Integrated Graphical Simulator Configuration Management Utility

Effective Training Session Monitoring and Debriefing

Emulating Multi-party Communications in Simulation Environments

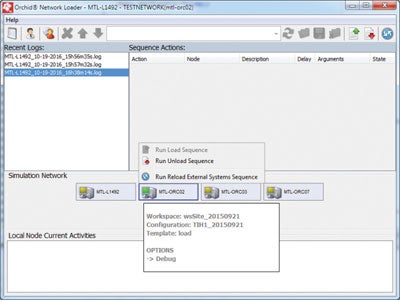

Multi-Platform Distributed Simulator Component Loader

Simulator Control Room Sound and Noise Utility

Versatile Simulator I/O Communication and Diagnostics

Related Solutions

Certifications | L3Harris Montreal, Canada

LEARN MOREAffiliations

Related News

Editorial | 02. 05. 2026

Al Seer Marine and L3Harris Deepen Strategic Agreement to Advance Maritime Unmanned Systems in the Middle East

Al Seer Marine and L3Harris have announced a strategic partnership combining UAE shipbuilding leadership with world-class autonomous maritime systems expertise. The collaboration will accelerate the development, integration, and deployment of advanced unmanned surface vessels across the UAE and broader region.

Contact Us