Overview

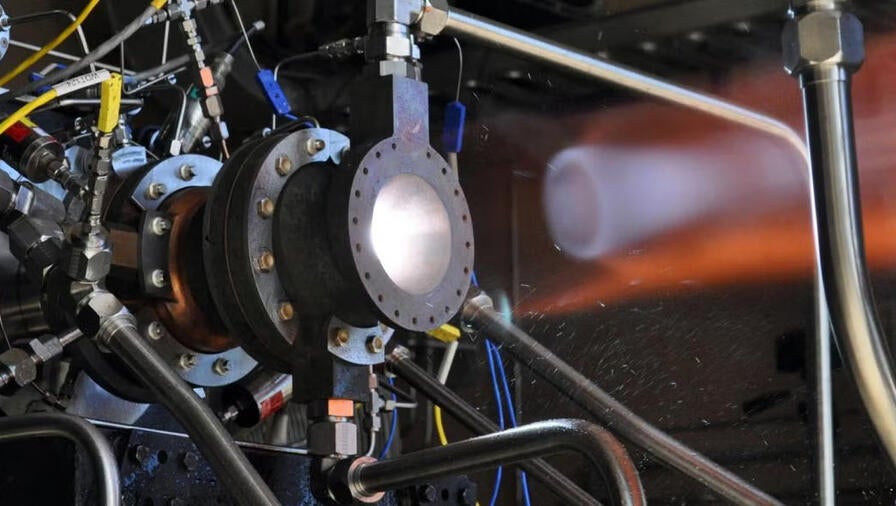

The Bantam engine family is being adapted from the proven design of the Atlas Sustainer engine to take full advantage of 3D printing capabilities. These engines, which would normally be composed of more than 100 parts, are built from only three 3D printed major components: the injector assembly, the combustion chamber; and a monolithic throat and nozzle section.