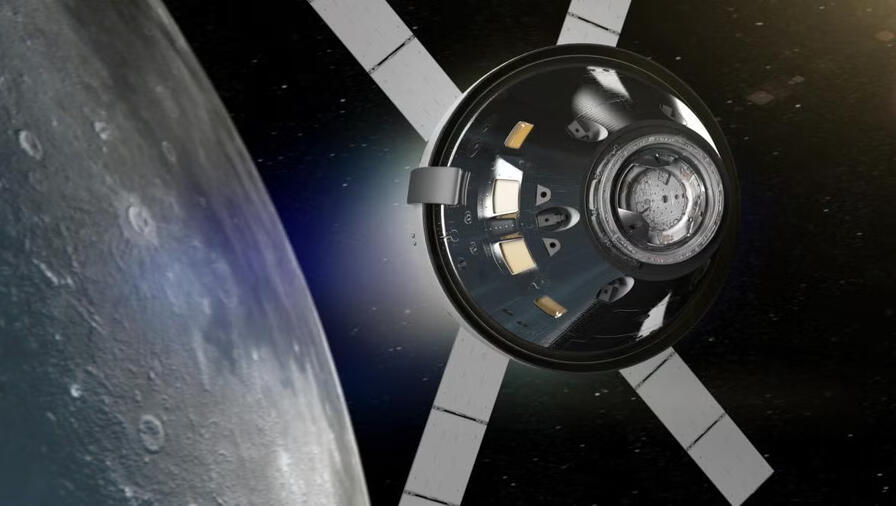

1,000-Day Mission Capability: Orion provides maximum radiation protection for its crew, an advanced life support system, and a heat shield that withstands the extreme temperatures of re-entry into Earth's atmosphere.

Full Redundancy: Incorporated into the Orion spacecraft is backup capability for all major avionics and crew systems.

Safe Emergency Abort Capability: Orion has a rocket-powered escape system designed to whisk the crew to safety in the unlikely event of a launch vehicle failure.

OUR ROLE

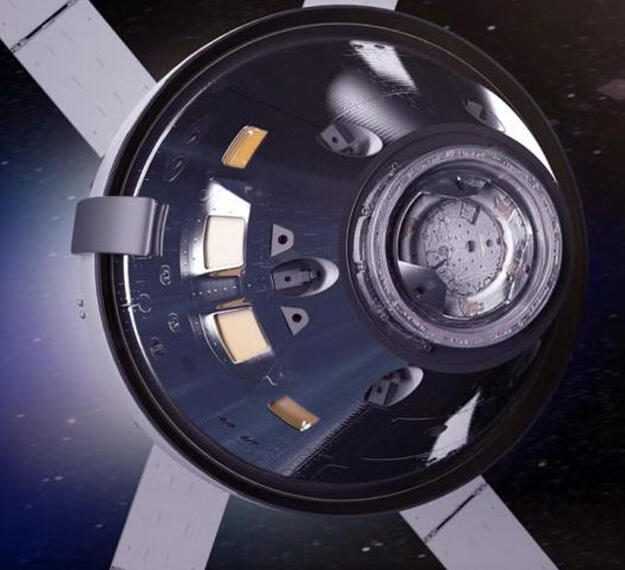

Orion Main Engine: L3Harris helped refurbish a regeneratively cooled, 6,000 pound-thrust bipropellant orbital maneuvering engine that was designed and built by the company and originally used on NASA’s space shuttle. The repurposed engine, mounted on the spacecraft’s European Service Module (ESM), provides the primary propulsion for Orion’s major in-space maneuvers.

Auxiliary Engines: L3Harris produces the Auxiliary Engines used to maintain Orion’s in-space trajectory and position, and provide backup to the main engine. Eight of these bipropellant engines, based on the flight-proven R4D engine family, are mounted on Orion’s ESM. The engines each provide 105 pounds of thrust for the Artemis I and II missions and 100 pounds of thrust for Artemis III and beyond.

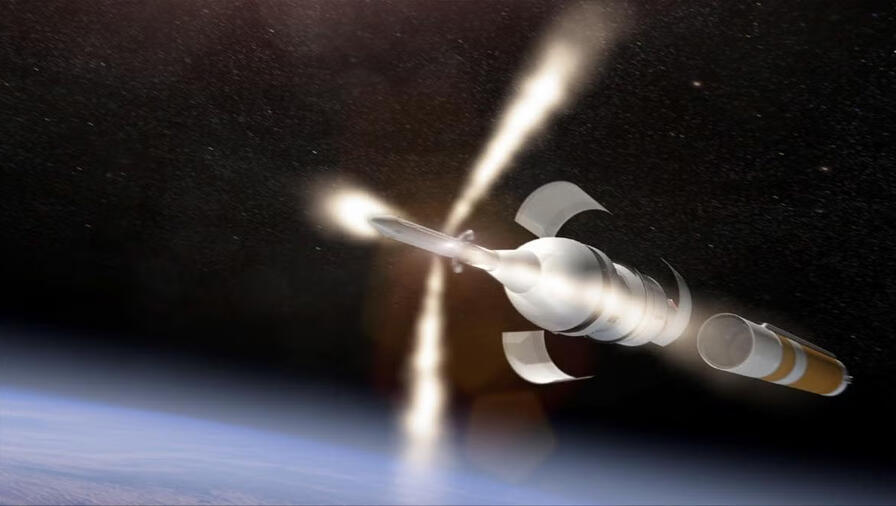

Launch Abort System Jettison Motor: Orion is outfitted with a Launch Abort System (LAS) that will rapidly separate the crew capsule from the launch vehicle in the unlikely event of a catastrophic event during launch or ascent. L3Harris builds the jettison motor that provides approximately 40,000 pounds of thrust to separate the LAS from the crew module, enabling the capsule and crew to safely land under parachutes. During a nominal mission, the jettison motor activates after stage-two ignition to separate the LAS from the spacecraft as the crewmembers continue their journey. This critical task makes it the only motor on the LAS to fire on every mission.

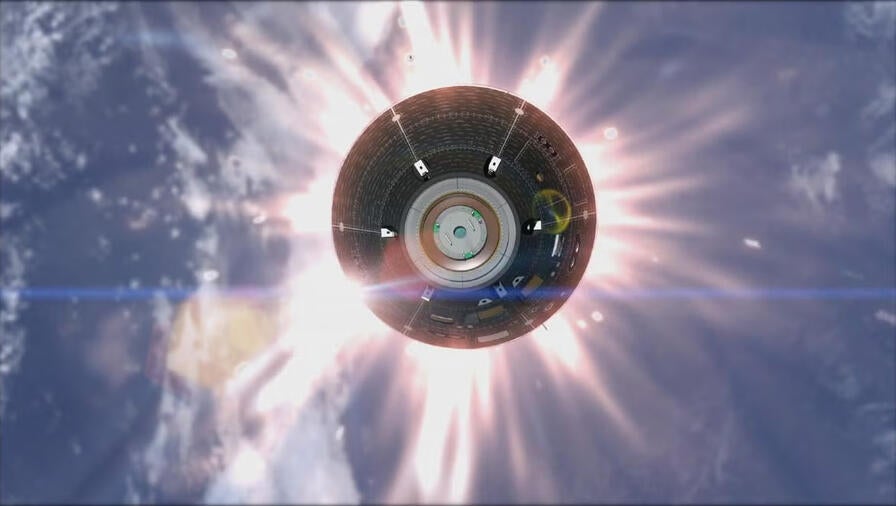

Reaction Control System: Prior to re-entering Earth’s atmosphere, the Orion crew module separates from the service module. After this point, L3Harris' Reaction Control System (RCS) becomes the sole means of controlling the crew module’s orientation during atmospheric re-entry and altering its course in preparation for splashdown. Twelve 160-pound-thrust monopropellant thrusters provide this critical function to the spacecraft.

Composite Overwrapped Pressure Vessels: After splashdown, Orion’s self-righting flotation system inflates five air bags with helium to maintain the capsule in an upright position, allowing the crew to safely exit the capsule through the hatch. The high-pressure helium is stored in five composite overwrapped pressure vessels (COPVs) produced by L3Harris’ subsidiary, ARDÉ. The Artemis I mission employed one nitrogen tank on Orion’s service module for cabin pressurization. Beginning with Artemis II, the first crewed Orion flight, ARDÉ is contracted to provide nitrogen and oxygen tanks for the spacecraft’s Environmental Control and Life Support System (ECLSS). Contracted through the fifth Artemis mission, these tanks will store the gasses needed to create a breathable atmosphere for astronauts in the crew module.